Description

INTRODUCE

The machine by our experience accumulated for many years to develop a new generation of high-speed rotary iron cover screw cap machine, the product can reach the international advanced level, is suitable for high speed production line 3 (4) spin iron cover screw cap seal, the machine adopts PLC control, touch screen operation, in the process of screw cap no injury, no damage phenomenon. Photoelectric sensors, proximity switches, etc are advanced sensing element, and advanced structure, smooth operation, low noise. Adopted catching cover positioning screw cap high-speed and accurate distribution of the lid and the bottle lid and synchronous operation.

PERFORMANCE CHARACTERISTICS

●The machine production speed, and infinitely adjustable speed, can adjust at will. Set into the bottle, catching cover, screw cap, and out of the bottle;

●In the running process, every key mechanical transmission parts adopt the mechanical and electrical integrated protection device. Machine in the process of running any abnormal, will automatically stop the alarm. Touch screen automatically tip machine abnormal spot;

●Man-machine interface, touch screen control, mobility operating platform, provide human nature to change more;

●It can customize according to customer's production 6 head head, 8, 10, 12, adapt to different production.

Technical Parameters

| Model | XHQL10 |

| Brand | DaChuan |

| Type | The weight of the |

| Packaging object | Plastic bottles, glass bottles, metal |

| Apply to industry | Food, cosmetic, pharmaceutical,

chemical and so on |

| Overall dimensions | 1700×1500×2200mm |

| Filling quotas | 10 |

| Production capacity | 12,000 bottles / h |

| Equipped with power supply | 380V |

| The host power | ≤3kw |

| Equipped with air | 0.6Mpa Clean and stable air source |

| The weight of the | 1.8T |

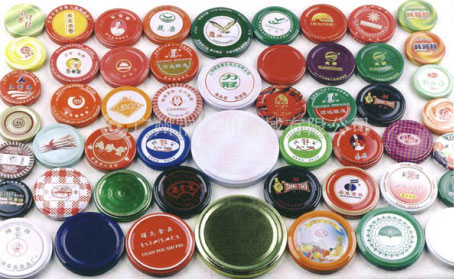

Reference map